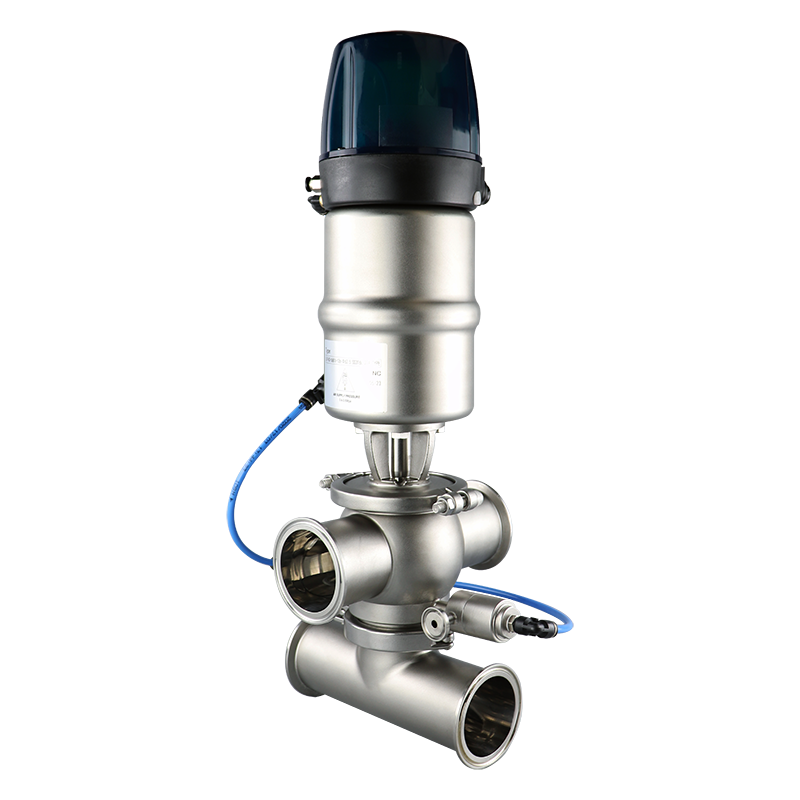

Current location:Home / Product / Anti mixing valve / Four way external cleaning anti mixing valve

application

This design is designed to ensure product mixing and leak detection when two different products flow through the same valve, and can replace the double seat anti mixing valve. It is widely used in industries such as food, brewing, beverages, dairy products, toothpaste, cosmetics, biopharmaceuticals, etc.

technical parameter

Specification: 1.5~ 4" DN40~DN100

Connection method: welding, clamps, threads, flanges

Maximum working pressure: ≤ 6bar

◆ Supply compressed air: 4-8bar

◆ Compressed air connection: Air pipe connector G1/8"

◆ Proximity switch: 6-36V DC 2 NPN or PNP (optional)

Input power supply: 24V DC

Working temperature: -10 ℃ to 120 ℃

◆ Part in contact with materials: SS304/SS316L

◆ Internal surface contact product: Ra ≤ 0.8 μ M

◆ Seals: EPDM, SI, FPM

operational principle

This valve is normally in a normally closed (NC) state and is equipped with two small pneumatic valves. Normally, it is in a normally open (NO) state and only needs to supply compressed air to the pneumatic head to synchronously close the two small valves. The main valve core is equipped with two independent seals, forming a leak detection and cleaning chamber between the two seals. Leaking products can flow out from the small valve outlets on both sides and the seals can be replaced in a timely manner. When performing CIP cleaning, the fluid flow direction is facing the square core of the valve core, which can comprehensively clean the main valve core (with a taper on the main valve core) and make the external CIP valve insensitive to water hammer effect. It can replace the double seat anti mixing valve as a valve array.

Related Information